- Laboratory information management system (LiMS)

- Enterprise resource planning (ERP)

- Visitor & Employee gatepass Management System

- Vehicle Control System

- Potent signage

- Management Information system (MIS)

- Watch Tower

- Real time monitoring of extrusion process

- Potent ABT system for Power Sector

- Potent Material Live Tracking

- Industrial automation 4.0 implementation

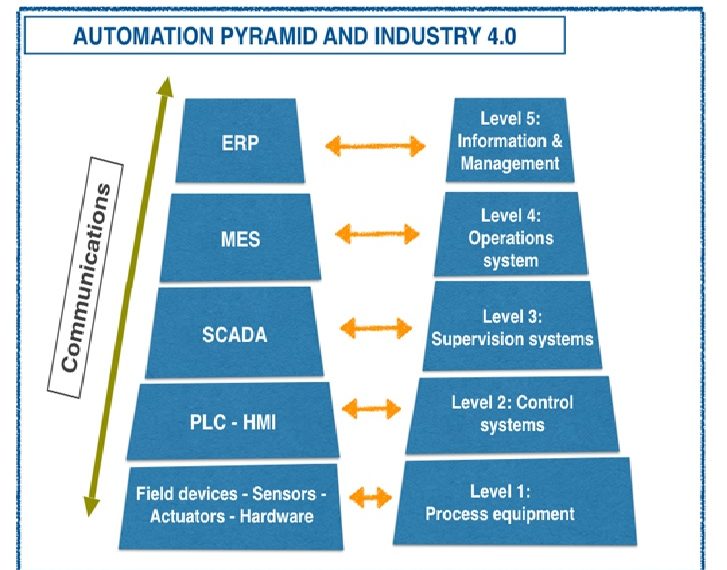

Industrial automation 4.0

Industry 4.0 refers to a new phase in the Industrial Revolution that focuses heavily on interconnectivity, automation, machine learning, and real-time data With the advent of Industry 4.0, the manufacturing industry has been undergoing a digital transformation. With automation and machine learning becoming more prevalent, manufacturing businesses are reaping the benefits – an increase in revenue and profit margins, as well as a reduction in costs.

Our company has created a new software that will revolutionize the manufacturing industry. Our software allows for better production and quality control by using machine learning and real-time data to identify problems in the production line

The First Industrial Revolution

The first industrial revolution happened between the late 1700s and early 1800s. During this period of time, manufacturing evolved from focusing on manual labor to heavy machinery. Just imagine, the amount of time people could spend on other tasks because they didn’t have to worry about operating machinery!

The Second Industrial Revolution

In the early part of the 20th century, the world entered a second industrial revolution with the introduction of steel and use of electricity in food processing. It was during this phase that mass production concepts like the assembly line were introduced as a way to boost productivity.

The Third Industrial Revolution

Starting in the late 1950s, a third industrial revolution slowly began to emerge, as manufacturers began incorporating more electronic—and eventually computer—technology into their factories. During this period, manufacturers began experiencing a shift that put less emphasis on analog and mechanical technology and more on digital technology and automation software.

The Fourth Industrial Revolution, or Industry 4.0

n the past few decades, a fourth industrial revolution has emerged, known as Industry 4.0. Industry 4.0 takes the emphasis on digital technology from recent decades to a whole new level with the help of interconnectivity. It connects physical with digital, and allows for better collaboration and access across departments, partners, vendors, product, and people. Industry 4.0 empowers business owners to better control and understand every aspect of their operation, and allows them to leverage instant data to boost productivity, improve processes, and drive growth.